Kala soocida Magnetic

| Summada | Amho |

| Nambarka Model | XYCF |

| Qalab | Birta kaarboon |

| Midabka La heli karo | Madow, caddaan, casaan, cawlan, jaalle. |

| MOQ | 1 |

| Adeegga QEM | waa la habeyn karaa |

| Baakad | Kiis alwaax ah |

| Lacag bixinta | Western Union, Money gram, Paypal,, Xawilaadda silig. |

| Rarida | Badda.Hawo |

| Waqtiga dirida | 15 maalmood gudahooda ka dib lacagtaada. |

| Cabirka Miisaanka: Codsiga: | Codsiga macmiilka ee aan caadiga ahayn Mashiinka wax lagu shiidayo |

Waxqabadka iyo Codsiga

Mashiinkan waxaa inta badan lagu dabaqaa dareeraha qaboojinta, goynta habka saliidda sifaynta ee qalabka wax lagu shiido iyo qalabka kale ee mishiinka giringirta giraangiraha, kordhinta nolosha adeegga gooyo, gaabin muddada beddelka ee dareeraha qaboojinta, iyo in la yareeyo xoojinta ka shaqeeya iyo wasakh deegaanka ee bulaacada.Waa qayb muhiim ah fuctional ee qalabka mishiinka shiidi iyo qalab kale oo goynta.

Astaamaha

1.Compact sizt, hawlgal xasiloon, buuq yar, isticmaalka tamarta hoose.

2.Tirada soo daaya chips-ka, wax xad-dhaaf ah malaha.

3.Waxa la soo saari karaa iyadoo loo eegayo booska la cayimay ee qalabka mashiinka.

Miiska dayactirka:

| Qayb hoose/ qayb | dhexda | Nooca shaqada | Tilmaamaha badbaadada |

| saxan dharbaaxo | 1 todobaad | Nadiifinta | Muddada u dhaxaysa waa la dheerayn karaa ama waa la gaabin karaa, iyadoo ku xidhan habka dheecaanku ka kooban yahay |

| 3 bilood | Iska hubi xidhashada iyo dhaawaca, hagaaji | Haddii ay dhacdo daal ama dhaawac xoog leh, beddel. hagaajin | |

| Silsilad wadista | 3 bilood | Hubi xiisadda oo haddii loo baahdo adkee, saliid. | Kaliya nooca leh silsiladda wadista. |

| Weelasha iyo isku dhafka tuubada. | 6 bilood | Iska hubi cidhiidhiga, daxalka iyo dhaawaca. | Walxaha waxyeelada u leh deegaanka lagama yaabo inay soo galaan xaalad kasta. |

| Matoorka Gear | ---- | Fiiri buug-tilmaameedka | |

| xajinta lidka ku ah | ---- | Dayactir la'aan | |

| Taangiyada qaboojinta. | 500 oo saacadood oo shaqo ah | Hubi wasakhaynta (meelaha dhoobada ah) oo nadiif ah | Iyada oo ku xidhan habka qalabaynta muddada u dhaxaysa ayaa laga yaabaa in si weyn loo soo gaabiyo. Taangiyada qaboojinta waa qalab gaar ah oo sidaas darteed laguma rakibo warshad kasta. |

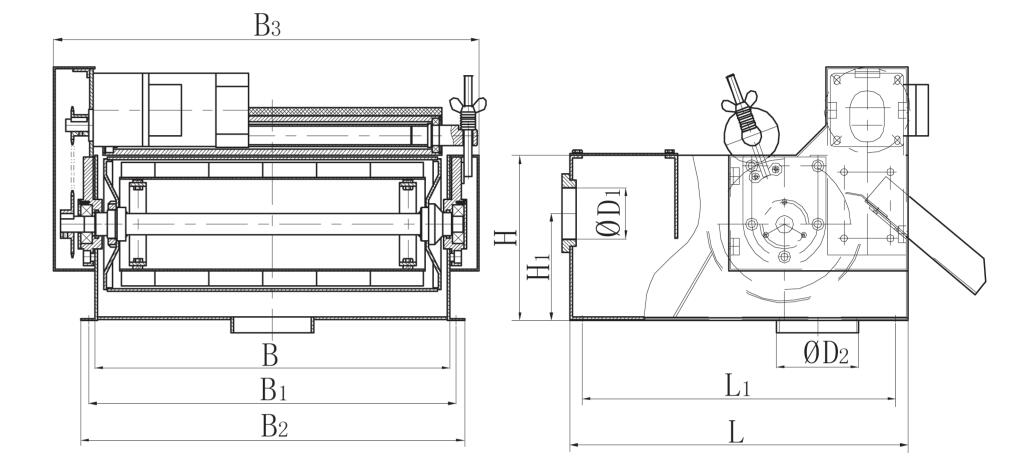

| Qaabka Qaabka | XYCF-25 | XYCF-50 | XYCF-75 | XYCF-100 | XYCF-200 | XYCF-300 | XYCF-400 | XYCF-500 |

| L (mm) | 320 | 360 | 380 | 410 | 520 | 540 | 540 | 600 |

| L1 (mm) | 290 | 330 | 320 | 380 | 490 | 500 | 500 | 560 |

| B(mm) | 216 | 300 | 380 | 430 | 600 | 730 | 810 | 952 |

| B1(mm) | 246 | 320 | 400 | 445 | 615 | 760 | 840 | 988 |

| B2(mm) | 265 | 336 | 416 | 465 | 636 | 780 | 860 | 1024 |

| B3(mm) | 301 | 385 | 465 | 515 | 685 | 833 | 911 | 1058 |

| H (mm) | 200 | 200 | 200 | 200 | 200 | 300 | 350 | 300 |

| H1 (mm) | 130 | 130 | 130 | 130 | 130 | 190 | 190 | 190 |

| D2 (mm) | 100 | 120 | 120 | 125 | 125 | 150 | 200 | 290 |

| Fiiro gaar ah: Cabirka kuwa kore waa badeecad caadi ah, waxaa loo habeyn karaa iyadoo loo eegayo shuruudaha macaamilka. | ||||||||

Sharaxaad:

Waxaa jira magnet joogto ah (ferrite ama neodymium iron boron,2 nooc oo ah xoojinta magnetic: 1000GS iyo 3000GS) gudaha durbaan magnetic.durbaanka birlabku waxa uu wareegaa oo uu wado matoorku.Marka dareeraha ay ku jiraan wasakhda birta birta magnetic u dhow yahay durbaanka magnetic, durbaanka magnetic wuxuu kala saari karaa wasakhda birta magnetic.Marka wasakhdu raacdo durbaanka magnetic ilaa qaybta sare, rullaluistemadka caaggu wuxuu dib u tuujiyaa dareeraha.Marka durbaanka birlabku uu wasakhda u wado xoqida, xoqitaanku wuxuu xoqaa wasakhda ku jirta durbaanka magnetic.Kala-soocida birlabeedka waxaa inta badan loo isticmaalaa sifaynta dareeraha qaboojinta (dareere goynta ama emulsion) ee mishiinka wax shiida iyo qalabka kale ee mishiinka.Si aad u isticmaasho kala-soocidda magnetic hoos u dhigi kartaa tirada shiidi sixitaanka wheel, hagaajinta dusha sare ee workpiece ah, dheerayn nolosha adeegga giraangiraha shiidi iyo dareeraha qaboojinta, la yareeyo xoogga shaqada ee shaqaalaha iyo in la yareeyo wasakheynta dareere qaboojinta deegaanka.Kala-soocida magnetic waxaa loo isticmaali karaa kaligiis, sidoo kale waxaa loo isticmaali karaa iyadoo lala kaashanayo filter band warqad, nadiifiyaha jajabka iyo kala-soocida vortex si kor loogu qaado saamaynta sifaynta.

Kala-soocida magnetic waxaa loo kala saari karaa kuwan soo socda iyadoo loo eegayo habka socodka:XYCF-25, XYCF-75, XYCF-100, XYCF-200, XYCF-300, XYCF-400, XYCF-500.

Sida loo doorto:

Guud ahaan, si aad u dooratid moodelku wuxuu ku xiran yahay heerka socodka qaboojiyaha ee looga baahan yahay goobta.Qodobbada ugu muhiimsan ee la tixgelinayo marka la dooranayo qaabka waxaa ka mid ah: socodka socodka, dhererka gudaha ee kala-soocida magnetic iyo booska rakibaadda ee goobta.Godka go'an ee kala-soocida magnetic waa 4-9.

Kala-soocida birlabku waxa kale oo laga samayn karaa matoor ku dhex dhisan nooc, magnet badhkii durbaanka magnetic iyo durbaanka magnetic wareega, laakiin ma wareeg ah ee magnet.