Magnetic Separator

| Brand | Amho |

| Model Number | XYCF |

| Material | Carbon steel |

| Available Color | Black,white,red,grey,yellow. |

| MOQ | 1 |

| QEM service | Can be customized |

| Packing | Plywood case |

| Payments | Western union, Money gram, Paypal,,Wire transfer. |

| Shipping | By sea.By air |

| Delivery time | Within 15working days after your payment. |

| WeightDimension:

Application: |

Non-standardCustomer request

Grinding machine |

Performance and Application

This machine is mainly applied for cooling liquid,cutting oil purification procedure of grinding equipment and other machine tools.It absorbs the tiny iron dust and attaching impurities within cooling liquid(oil) by the magnetic drum of separator.It can reduce the correction times of gringing wheel,extend service life of cutters,shorten the replacing period of cooling liquid,and reduce intensity of operators and environmental pollution of sewage.It is an important fuctional part of grinding machine tool and other cutting equipment.

Characteristics

1.Compact sizt,stable operation,low noise,low power consumption.

2.Discharge chips quantitatively, no overloading..

3.It can be manufactured according to specified space of the machine tool.

Maintenance table:

| Subassembly/

component |

Interval | Type of work | Safety instruction/remark |

| Stripping plate | 1 week | Cleaning | The interval can be prolonged or shortened,depending on the composition of the discharge |

| 3 months | Check for wear and damage,adjust | In case of strong wear or damage,replace.Adjustment. | |

| Driving chain | 3 months | Check the tension and if necessary tighten, oil. | Only for version with driving chain. |

| Containers and hose assemblies. | 6 months | Check for tightness,corrosion and damage. | Substances harmful to the environment may not penetrate under any circumstances. |

| Gear motor | ---- | See instruction manual | |

| Antifriction bearing | ---- | Maintenance-free | |

| Coolant tanks. | 500 working hours | Check for contamination (sludge deposits)and clean | Depending on the tooling method the interval may be greatly shortened.

Cooling tanks are special accessories and are therefore not installed in every plant. |

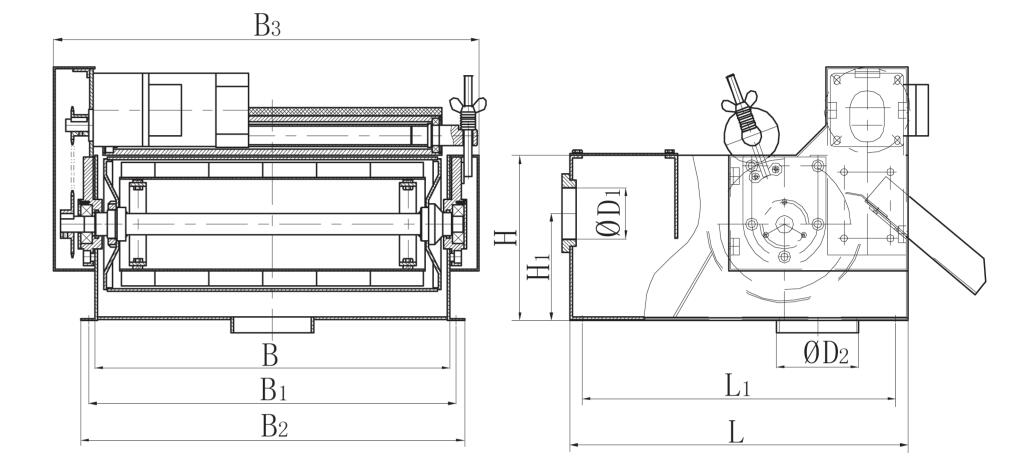

| ModelSize | XYCF-25 | XYCF-50 | XYCF-75 | XYCF-100 | XYCF-200 | XYCF-300 | XYCF-400 | XYCF-500 |

| L(mm) | 320 | 360 | 380 | 410 | 520 | 540 | 540 | 600 |

| L1(mm) | 290 | 330 | 320 | 380 | 490 | 500 | 500 | 560 |

| B(mm) | 216 | 300 | 380 | 430 | 600 | 730 | 810 | 952 |

| B1(mm) | 246 | 320 | 400 | 445 | 615 | 760 | 840 | 988 |

| B2(mm) | 265 | 336 | 416 | 465 | 636 | 780 | 860 | 1024 |

| B3(mm) | 301 | 385 | 465 | 515 | 685 | 833 | 911 | 1058 |

| H(mm) | 200 | 200 | 200 | 200 | 200 | 300 | 350 | 300 |

| H1(mm) | 130 | 130 | 130 | 130 | 130 | 190 | 190 | 190 |

| D2(mm) | 100 | 120 | 120 | 125 | 125 | 150 | 200 | 290 |

| Note: The size of the above is standard product, can be customized according to customer’s requirement. | ||||||||

Description:

There is permanent magnet(ferrite or neodymium iron boron,2 kinds of magnetic intensities:1000GS and 3000GS) inside the magnetic drum. the magnetic drum rotates driven by the motor. when liquid containing magnetic iron impurity is near the magnetic drum, the magnetic drum can separate the magnetic iron impurity. When impurities follow the magnetic drum to the upper part, the rubber roller squeezes the liquid back. When the magnetic drum drives the impurity to the scraper ,the scraper scrapes off the impurities on the magnetic drum. The magnetic separator is mainly used for the purification of the cooling liquid(cutting fluid or emulsion) of the grinding machine and other machine tools. To use magnetic separators can reduce the numbers of grinding wheel correction, improve the surface finish of the workpiece, prolong the service life of the grinding wheel and cooling fluid, reduce the labor intensity of workers and reduce the pollution of cooling liquid to the environment. Magnetic separator can be used alone, and also can be used in conjunction with paper band filter, chip cleaner and vortex separator to enhance the filtration effect.

Magnetic separator can be classified into the following according to the process flow:XYCF-25, XYCF-75, XYCF-100, XYCF-200, XYCF-300, XYCF-400, XYCF-500.

How to select:

Generally speaking, to choose which model depends on the coolant flow rate needed at the site. The main factors to consider in choosing the model include: process flow, the inlet height of the magnetic separator and installation space at the site. The magnetic separator’s fixed hole is 4-9.

Magnetic separator can also be made into motor built-in type, half magnetic for the magnetic drum and the magnetic drum rotating, but no rotation for magnet.