Flat bed paper filter,coolant filter for grinding machine

| Brand | Amho |

| Model Number | XYGL |

| Material | Carbon steel |

| Available Color | Black,white,red,grey,yellow. |

| MOQ | 1 |

| QEM service | Can be customized |

| Packing | Plywood case |

| Payments | Western union, Money gram, Paypal,,Wire transfer. |

| Shipping | By sea.By air |

| Delivery time | Within 15working days after your payment. |

| WeightDimension:Application: | Non-standardCustomer requestGrinding machine |

Performance and Application

This machine can filter and remove both metal and nonmetal impurities within cooling liquid effectively by the non-woven on filter screen. As a functional part of various grinding machine tools, it filters cooling liquid thoroughly, extends service life of cooling liquid, enhances machining quality of work pieces and improves cutting environment.

Characteristics

1.Compact size, low noise, convenient for installing at the outlet of machine tool.

2.For the convenience of installation, positions of motor and electric cabinet can be decided according to users’ requirement.

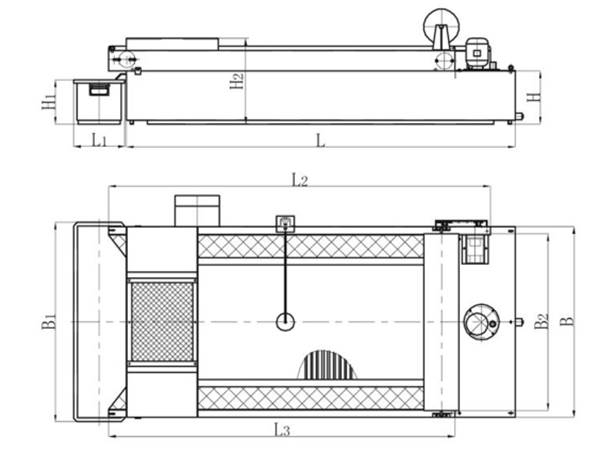

| ModelSize | XYGL1-25 | XYGL1-50 | XYGL1-75 | XYGL1-100 | XYGL1-150 | XYGL1-200 | XYGL1-250 | XYGL1-300 |

| L(mm) | 1050 | 1200 | 1600 | 1600 | 1800 | 2200 | 2540 | 3000 |

| L1(mm) | 250 | 250 | 250 | 290 | 290 | 290 | 290 | 450 |

| L2(mm) | 990 | 1160 | 1560 | 1560 | 1760 | 2160 | 2160 | 2765 |

| L3(mm) | 840 | 960 | 1360 | 1360 | 1560 | 1960 | 1960 | 2565 |

| B(mm) | 460 | 600 | 600 | 800 | 1080 | 1080 | 1080 | 1080 |

| B1(mm) | 490 | 650 | 650 | 850 | 1130 | 1130 | 1130 | 1130 |

| B2(mm) | 400 | 520 | 520 | 720 | 1000 | 1000 | 1000 | 1000 |

| H(mm) | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 530 |

| H1(mm) | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 450 |

| H2(mm) | 445 | 450 | 450 | 465 | 465 | 465 | 465 | 665 |

| Note: The size of the above is standard product, can be customized according to customer’s requirement. | ||||||||

Description

It filters by filtering paper,before working,we should first spread the filter paper on the chain network.Then the emulsion or oil flows to the filtering paper.The liquid follows to the liquid tank,and the impurities are segregated on the filter paper.When the impurities on the filter paper become more,the emulsion can not go through,then a liquid pool is formed on the filter paper.The liquid level floating ball goes up,then it drives the paper motor to work.the used-up paper is pulled out,and a new paper will spread on the filter automatically.the process goes around like this.The filtration precision is determined by filter paper.Normally,the filter accuracy is 10-30μm.

Paper band filter is mainly used for filtering the coolant for various machine tool.This device has a pollution,improve effective working hours,reduce the labor intensive of the operator of the machine tool.It also increases the surface finish of the workpiece and improve the quality of the products.

How to select

To choose which kind of model is determined by the flow rate of the grinder,moreover the height of backwater and installation space should be considered.According to the installation dimension,if the standard products is not proper,we can make it as your requirement.

Maintenance table

| Subassembly/ component | Interval | Action | Safety instructions/ remarks |

| DriveDrive chain | 3 months | Check tension and tighten if necessary, lubricate drive chain | |

| Bearing of drive shaft and guide roller | —- —- | Check wear and play | When conveying belt is damaged, check and replace if necessary |

| Electrical equipmentMotor(s) | —- —- | See operating instructions of manufacturer | |

| Wiring | 3 months | Check for ruptures and damage | Replace defective wiring |

| Level switch | 3 months | Check function | Exceed both switch points by manual actuation |

| Protective gear | 3 months | Check function | |

| Pumps | —-—- | See operating instructions of manufacturer | |

| Containers | 6 months | Check for leaks, damage and corrosion | Ensure that no hazardous sub- stances escape |

| Conveying belt | 6 months | Check for damage | Replace conveying belt when damaged |